Instant coffee has become an indispensable part of modern life thanks to its convenience and distinctive flavor. However, few people know that behind every granule of instant coffee lies a meticulous production process that requires advanced technology and attention to every detail. Let’s take a deeper look at how is instant coffee made, analyzing the technical and technological factors that influence the final product’s quality.

Selecting raw materials

Every high-quality instant coffee product starts with carefully selecting raw materials, which play a decisive role in shaping flavor and quality. Robusta and Arabica coffee beans are commonly used, with careful consideration of caffeine content, acidity, and natural aroma.

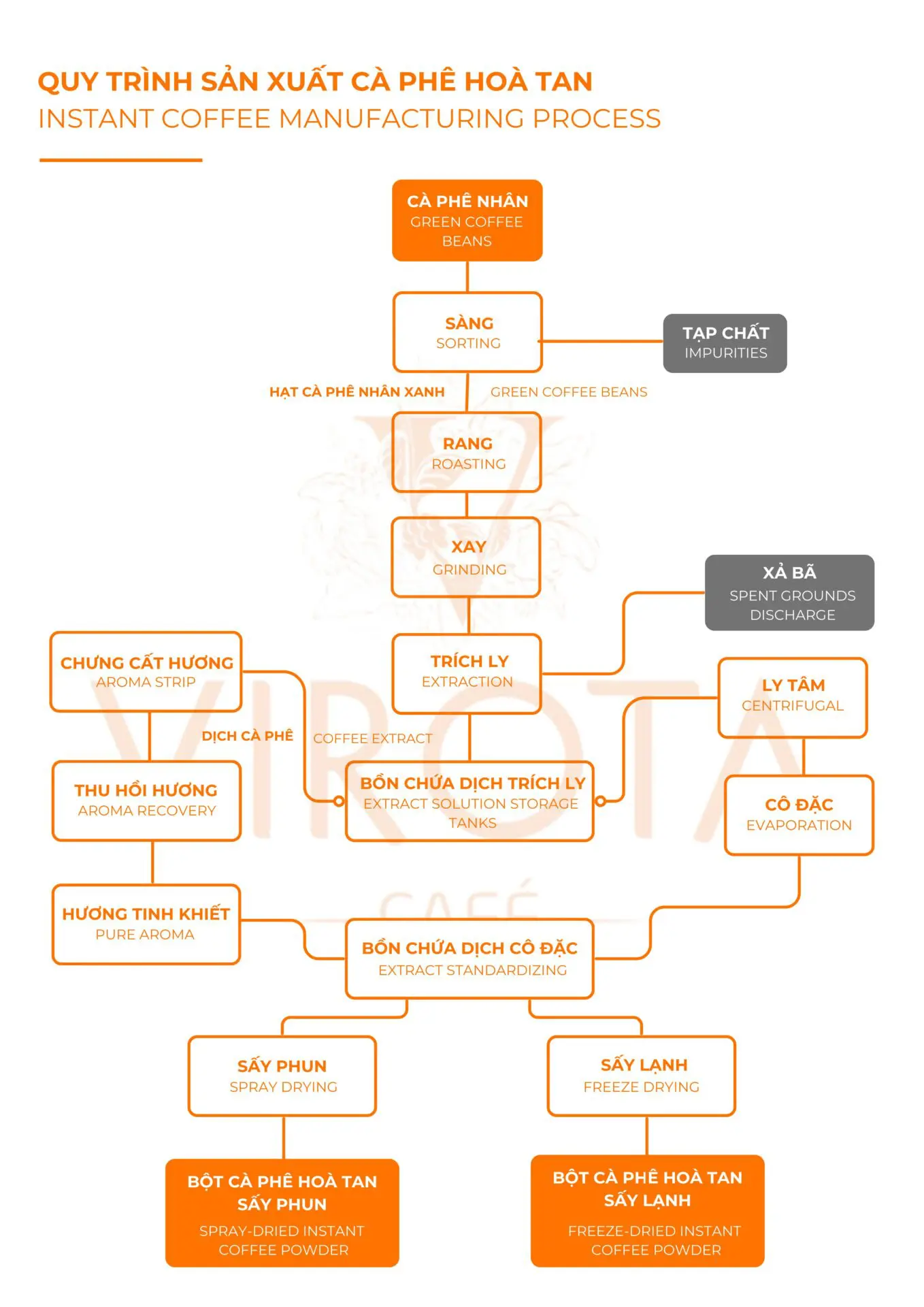

- Cleaning and sorting: Manufacturers use advanced technology such as mechanical sieving and optical analysis to remove impurities like soil, stones, and defective beans.

- Origin control: The current trend is to prioritize sustainably grown coffee from renowned regions, ensuring transparency and consistent quality.

The choice of raw materials not only affects the flavor but also determines the retention of essential organic compounds in subsequent processing stages, which is particularly important in the instant coffee industry.

Modern manufacturers also use optical technology to analyze the color and size of coffee beans, ensuring that only the best beans are selected for production.

Instant coffee production process: from bean to final product

Roasting and grinding: unlocking flavor potential

Roasting coffee is not only the process of cooking the beans but also an art that brings out hundreds of natural aromatic compounds present in coffee.

- Roasting temperature and time: The roasting process typically occurs at temperatures between 190-240°C, lasting 18-25 minutes depending on the bean type and flavor profile. Modern roasting systems use temperature and humidity sensors to ensure uniformity across batches.

- Grinding: After roasting, the coffee is ground into a coarser powder than traditional brewing coffee, optimizing extraction efficiency in the next step.

Precise control of roasting temperature and cooling speed is crucial in balancing bitterness, caramelized sweetness, and delicate acidity.

Extraction: preserving delicate flavors

Coffee extraction is the stage where key compounds such as caffeine, coffee oils, and aromatic components dissolve into hot water.

- Temperature and pressure: The ideal extraction temperature is between 80-90°C, combined with high pressure to yield a coffee concentrate of 30-35%, preserving essential compounds.

- Multistage extraction system: Some manufacturers use multi-stage extraction systems, allowing coffee solutions to circulate through multiple layers of ground coffee to enhance solubility.

This process not only affects coffee concentration but also determines flavor depth, balance between bitterness and natural sweetness, and aroma retention after preparation.

Concentration: enhancing intensity

After extraction, the coffee solution is concentrated using modern vacuum systems to minimize water content while preserving flavor.

- Concentration method: Low-pressure technology is used to allow water to evaporate at lower temperatures, protecting volatile aromatic compounds.

Aroma recovery

The natural aroma of coffee is often lost during extraction and drying. Therefore, recovering and reintroducing aromas is a crucial step in modern production.

Volatile aromatic compounds are separated from the coffee solution before evaporation and then reintroduced to ensure that instant coffee retains its original flavor and aroma.

Drying

Instant coffee is typically produced using two main drying methods:

- Spray drying: The coffee solution is sprayed into fine mist droplets in a hot air chamber, where the particles dry quickly and fall to the bottom. This method produces smooth, uniform coffee granules.

- Freeze drying: Also known as lyophilization, this process starts by freezing the coffee solution at -50°C, followed by sublimation to remove water. This method preserves nearly all natural flavors but comes with significantly higher production costs.

The choice between spray drying and freeze drying depends on product goals and target markets. Spray drying is suitable for mass production, while freeze drying is preferred for premium coffee lines.

>> See more: Instant coffee production system at Virota Cafe

Emerging trends in the instant coffee industry

- Blended products: Instant coffee is increasingly combined with ingredients like collagen, protein, or herbs to meet health and wellness demands.

- Sustainable packaging: Modern packaging not only protects the product but is also designed to minimize environmental impact, such as using biodegradable materials.

>> See more Virota Cafe instant coffee products

Instant coffee is not just a product of convenience but a testament to remarkable advancements in food processing technology. From raw material selection to extraction and aroma recovery, each step is a harmonious blend of science and artistry, creating a high-quality product suited to modern lifestyles.

With continuous innovations in the industry, instant coffee is solidifying its position in the global market, catering to a diverse range of consumers—from those seeking convenience to those desiring an authentic coffee experience

___________________

Contact us:

- Address: Lot A18 – A19 Dien Phu Industrial Park, Dien Khanh, Khanh Hoa, Vietnam

- Email: marketingvirota@gmail.com

- Phone: (+84) 866 460 999

- Fanpage: Virota Cafe

- Youtube: Virota Cafe channel

- LinkedIn: Virota Cafe LinkedIn

- Twitter: Virota Cafe twitter